Tube Threading Machine

Steelaa Solutions offers both manual as well as automatic Tube Threading machine to produce threads as per International standards at avery high output rate with quick tool change system.

Features:

- Automatic Operation

- High Production upto 12 Tubes/Min depending up on the Outer Diameter

- Threading Heads both Imported as well as Domestic are available

- High Quality chasers for accurate threading of the Pipe and Tube

- Quick Tool Changing system

Specifications:

- Minimum OD 21.30 mm

- Maximum OD 114.30 mm

- Standard BS21/ASTM A53

Tube End Facer

Steelaa Solutiions offer both manual as well as Cam operated Twin Head End Facer with three tool system.

Features:

- Fully Automatic

- Three Tooling System for OD, ID and Face Chamferring at the same time

- Tooling either Carbide or HSS for quality for quality end facing

Specifications:

- Minimum OD 12.70 mm with Minimum Wall Thickness 0.80 mm

- Maximum OD 219.30 mm with Maximum Wall Thickness 8.00 mm

- Minimum out put 04 and the Maximum 20 Tubes/Min depending up on the quality of the input Tubes

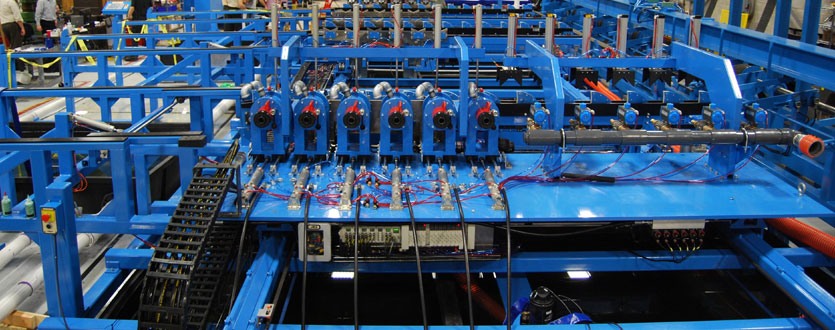

Hydro Tester

Steelaa Solutions offers Hydrotesters equipped with oil/water high pressure up to 5000 psi intensifiers with automatic handling system and chart type pressure recorder in accordance with the International Standards such as API/ASTM/BS.

Features:

- Oil and Water Intensifier

- OD Sealing Type

- Quick Change Toolings

- Computerised Data System

Specifications:

- Minimum OD 12.70 mm with minimum wall thickness 0.80 mm

- Maximum OD 219.3 mm with maximum Wall Thickness 8.00 mm

- Minimum Test Pressure 3000 psi and the maximum 5000 psi

Tube Straightening Machine

Steelaa offers hydraulically operated Two/Four. Die Tube Push Pointing Machine, suitable for both Ferrous and Non-Ferrous material for pointing of tubes prior to cold drawing, having many advantage over the conventional swaging/squeeze pointing operations. The machine is also capable of Nozzeling the point.

Features:

- Noiseless and Vibration free operation.

- Improved productivity & yield in cold drawing

- Considerable material saving

- Perfectly round concentric point suitable for thin or thick wall tubes.

- No loss of point in multi sided gripper jaws.

- Common die for pointing and cold drawing

- Computerised data acquisition system.

- Automatic handling system with rubberized rollers.

Specifications:

- Maximum Push Force(MT): 23, 34, 34/68

- Maximum OD 90 to 130 mm

Tube Draw Bench

Steelaa offers Single / Double / Triple Type Draw Benched with automatic operation for high yield, perfect quality and precise application.

Features:

- Automatic tube feeding mechanism.

- Motorized Rotating / Indexing Type Back Bench with automatic plug positioning device to minimum handling time.

- Spherical die holder for self-alignment.

- Fully Guided Carriage with automatic fast return.

- Round tooth type pneumatic clamps to avoid fast return

- DC Regenerative Drive for power saving

- Heavy Duty, high reduction gear box.

- Carriage driven by duplex/Triplex type double sprocket & chain having rupture strength 6

- Times of the draw force.

- Automatic Tube Discharge at Front Frame.

Specifications:

- Maximum Pull Force (MT): 10 to 75

- Maximum Mother Tube OD (MM): 50 to 175

- Maximum Drawn Tube Length (Meter): 18 to 25

- Maximum Draw Drawing Speed (Max/Min): 60 to 36